Hot melt adhesives are solvent-free formulations which become liquid when heated and are applied in molten state.

To achieve a good degree of wetting, the substrates have to be joined within the open time. Hot melts are characterised by a very rapid build-up of internal strength on cooling. They are physically hardening thermoplastic adhesives which are already present in their final chemical state.

Modern hot melt adhesives in our portfoglio impress with excellent processing characteristics and a broad spectrum of adhesion to different materials.

Short setting times facilitate a fast downline processing and therefore fast production speeds.

We are ready to supply a wide range of different high-performance adhesives with special properties which provide an ideal process solution for even the most specific and complex requirements.

PRODUCT SERIES, PROPERTIES AND APPLICATION

CoPA Hot Melt Adhesive

Basis : Copolyamides

Properties : Products with high heat resistance and/or higher resistance to solvents/plasticisers compared to PO hot melt adhesives.

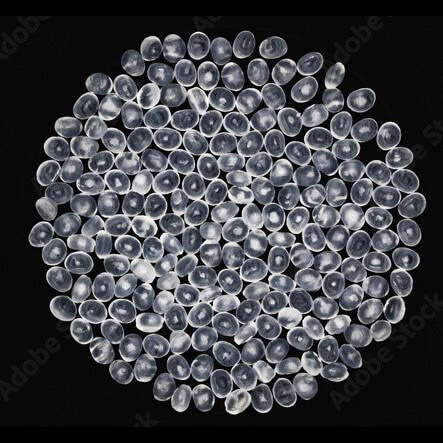

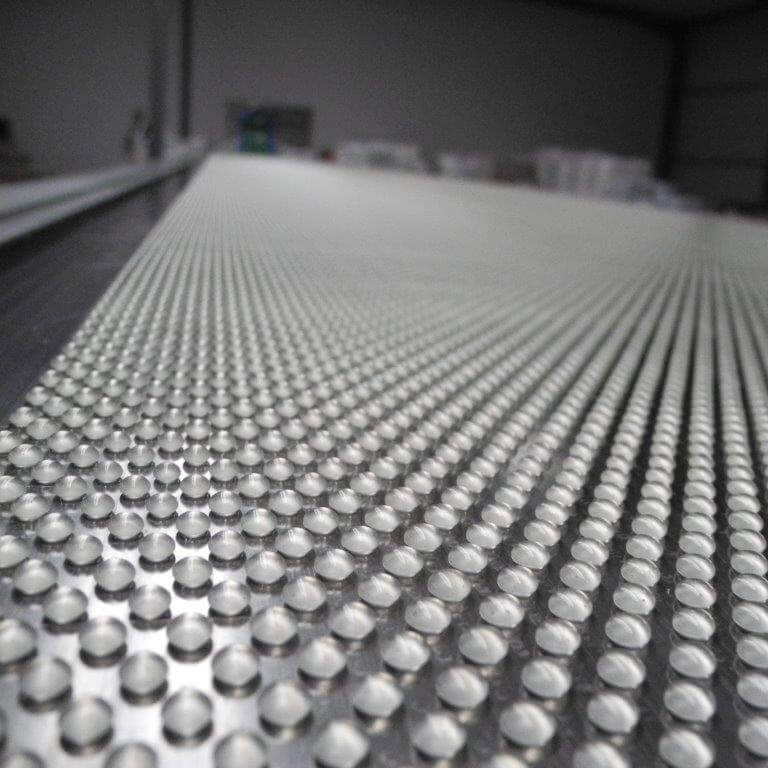

Packaking : Granulate

Brand : Sentatherm, Jowatherm

EVA Hot Melt Adhesive

Basis : Copolymer based on ethylene vinyl acetate

Properties : Good heat resistance, low resistance to solvents and plasticisers.

Packaging : Granulate, blocks, drums

Brand : Sentatherm, Jowatherm

PO Hot Melt Adhesive

Basis : Polyolefin (based on different monomers, e.g. ethene, propene, butene, hexene)

Properties : High heat resistance, very good oxidation stability (low charring tendency), very good adhesion, narrow molecular weight distribution, low fogging, low resistance to solvents and plasticisers.

Packaging : Granulate, pillows, blocks, drums

Brand : Senta-Toptherm, Jowat-Toptherm

Bio-based Adhesive

Basis : Bio-based

Properties : Clean processing and low maintenance, resource-efficient and recycling-friendly, certified sustainability.

Packaging : Granulate

Brand : Senta Grow, Jowatherm Grow