Manufacturing of Foam Mattresses

Create the best bond

Good mattresses are the basis of a restful sleep and regeneration. Adhesives play a major role in the manufacturing process of mattresses. In addition to bonding different substrates, adhesives also help increasing comfort and health and therefore support a good night’s sleep.

We can supply a broad range of innovative products for all processes in the manufacturing of mattresses. Besides higher expectations regarding their long term resistance, the adhesives are easy to process, even while the technological requirements and material diversity are increasing.

We are able to serve with thermoplastic and reactive hot melts and solvent-based adhesives tailored for each specific application.

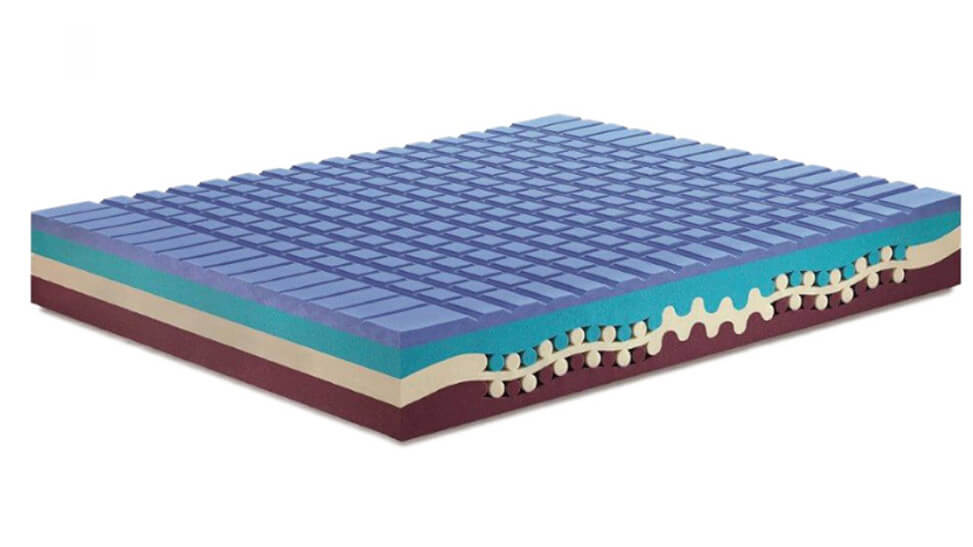

In the manufacturing of foam mattresses, an increasing number of layers of sometimes different foams are laminated to each other. The adhesive used in this application has to be highly flexible and adhere to a wide range of materials. PUR hot melt adhesives meet these demands and provide a significantly faster build-up of strength compared to the frequently used dispersion adhesives. Therefore they facilitate more efficient manufacturing processes due to faster mattress packaging with less energy consumption.

The quality of a mattress is determined by its structure, the processed materials, the used adhesive and the related assembly process. Apart from quality, efficiency plays an essential role for mattress manufacturers. In this context, efficiency means especially an excellent cost-benefit ratio, high productivity in the assembly of the mattresses and in the following processes like filling, packing and shipping.

Minimal production costs, short process cycles, easy handling with a low potential for errors in the assembly are decisive factors in the global competition. Effectiveness can be increased by reducing and preventing inefficient waiting times and transport routes. The adhesive for mattress assembly has to support the virtually unlimited structure diversity and be characterised by good adhesion also to substrates which are difficult to bond, such as latex, viscose or gel foams.